Analysis of Your Control

I’m willing to provide an analysis of how good the control of your tensile properties at no charge.

What You Get

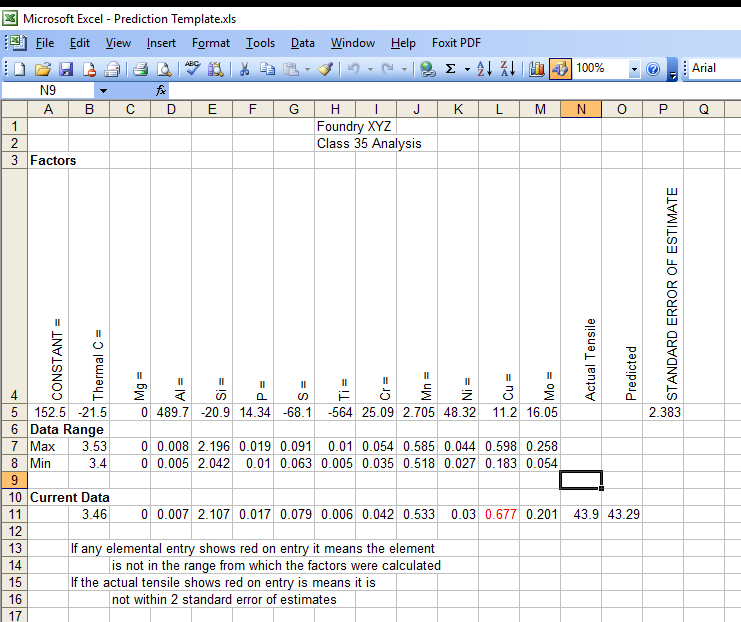

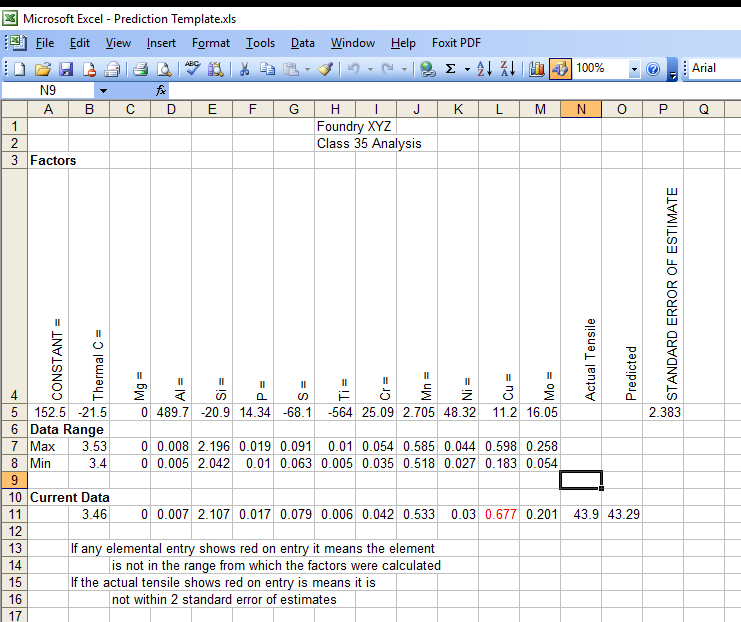

I will supply you with a spread sheet that allows you to predict what tensile properties you’ll achieve from the chemistry you enter based on what you have done before. If you also have the properties actually achieved from the chemistry, it will tell you if the results were within statistical norms.

Example of Spreadsheet

In addition, I will provide you with my insights on the control exhibited in the data you have sent me.

What I need

In order to receive the analysis you will need to send me a spread sheet containing the chemistry and tensile properties from at least 25 tests. (More than 25 is not a problem.

While I’ll provide the analysis if you want to lump all your data together, it looses meaning and the predictions lose accuracy as compared to analyzing data that is all from the same grade of iron. I have no problem doing multiple analyses for different grades from the same foundry. Of course, you’re informing me of what grade you were trying to achieve will allow a more complete analysis of your results.

I don’t apply any limits to the number of elements in the analysis; however, all of the samples will have to the same elements. (If you have some samples where your spectrometer gives a less than reading, it will be treated as reading zero.) There is also not a limit on how the chemistries are obtained. I know some foundries obtain chemistries only daily, per shift, or per hour. Analysis done with those chemistries will be far less meaningful. The best results are obtained when the chemistries are obtained from the same iron that the tensile specimen was poured.

Finally, as cooling rate affects tensile properties, all of the tensile specimens should be poured in molds from the same pattern. Of course, I’d recommend using one of the ASTM standard specimens, but I realize there may be reasons for foundries needing to use some other configuration.

Why

Being one of a suspicious nature, if I were you, I’d be wondering why someone would be willing to offer to perform such an analysis at no charge. What’s the catch?

There are a number of reasons. First and foremost, I have been intrigued by controlling tensile properties for a number of years. As can be seen by some of the articles showing up here I’ve worked on controlling tensile properties for years. I believe I’ve made some strides in improving the control. While the data with the foundries I’ve worked with does show they work, it is from a limited number of foundries. Having the information from more foundries will allow me more certainty that my theories are correct.

My hope is once the analysis is received, you will use it to see if the analysis does predict what is happening in your operation. If you go that far and I’m correct, I’m confident you will start asking what can you do to improve the control. There will be numerous different answers to that question. One answer will be to contact me to see if I believe I can be of assistance.

That being said, you supplying the data for analysis will not put you on a mailing list of any kind. Other than sending you the analysis to you upon its completion, I will contact you only if I have a question about your data. Once I send the analysis, I will not contact you again unless it is in response to you contacting me. That includes, of course, responding to any questions you may have about the analysis.

If you have further questions about why I’m doing this or anything else, please feel free to contact me directly.

Roy Lobenhofer

847.640.8065